Hydrotesting large-scale infrastructure is never a matter of simply turning on a tap. It requires precision, unwavering pressure stability, and the ability to adapt to complex site geometries.

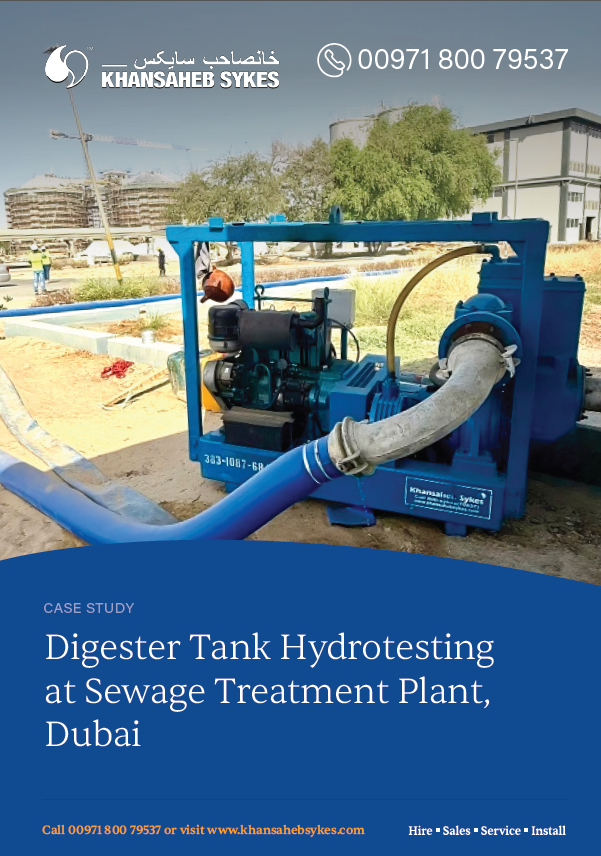

Khansaheb Sykes recently supported a critical upgrade at a Sewage Treatment Plant in Dubai. The scope involved the hydrotesting of two massive digester tanks, each boasting a capacity of 11,500 m³ requiring a pump setup capable of sustaining performance over a month-long testing period.

Elevation and Access Constraints

The logistical hurdles on site were immediate. While the tanks demanded high-volume filling, their connection points stood well above ground level. Complicating matters, the designated working area lay inside an excavated zone, making direct hose access physically impossible.

To add to the complexity:

- No Scaffolding: There was no infrastructure available to support a straight-line hose connection.

- Complex Routing: Hoses had to be routed down into the excavation and then vertically back up to the PN10 tank inlet.

- Pressure Integrity: Despite the routing convoluted “U-shape,” the system had to maintain stable pressure without leakage or flow drop-off.

Custom Engineering with the GP150

As standard setups would not suffice for this geometry. To overcome these constraints, our engineering team deployed the Sykes GP150 General Purpose Pump, configured with suitable rubber and lay-flat hoses, along with customised fittings designed to match the elevated PN10 inlet connection.

To bridge the gap between the excavation and the elevated inlet, we engineered a bespoke solution:

- Custom Fittings: We fabricated specific fittings to mate perfectly with the tank’s elevated PN10 inlet connection.

- Flexible Routing: A combination of heavy-duty rubber and lay-flat hoses was utilized to navigate the excavation safely without restricting flow.

- Active Monitoring: Our technicians maintained a presence on-site to monitor flow and pressure, ensuring the pump compensated for the friction loss caused by the complex hose route.

Our team carefully planned the hose routing to navigate the excavation safely while ensuring uninterrupted flow. Throughout the operation, the team closely monitored pressure and flow rates to guarantee safe, efficient, and consistent hydrotesting performance across both digester tanks.

This tailored setup allowed the project to progress without disruption, despite the complex access conditions on site.

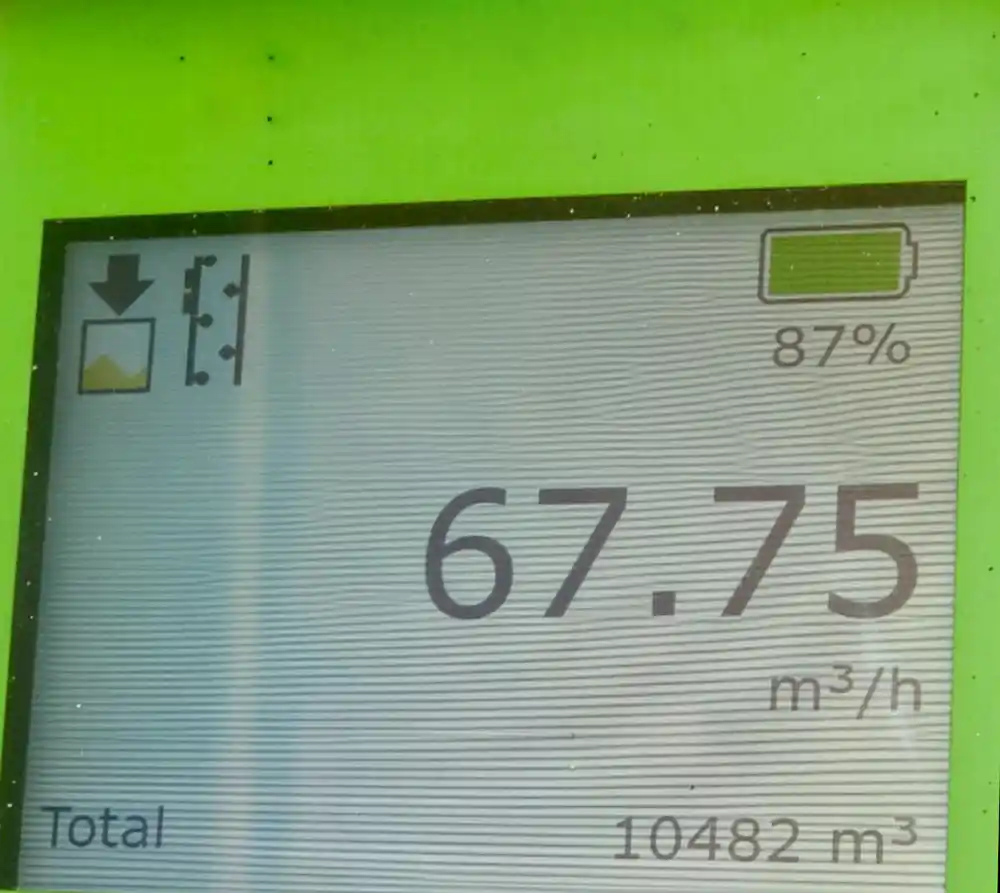

Exceeding Flow Targets

Despite the challenging access conditions, the hydrotesting operation proceeded seamlessly. The Khansaheb Sykes solution did not just meet the technical requirements; it surpassed them.

Target Flow: 60 m³/hr at 2-3 bar.

Achieved Flow: Recorded rates topping 67+ m³/hr.

Efficiency: Each tank was filled and tested successfully within a 15-day window.

The client confirmed the strong performance of the pumping system, noting that the equipment reliability was crucial for keeping the upgrade project on schedule. This project reinforces our commitment to not just hiring out equipment, but engineering solutions that overcome the physical realities of the construction site.

Delivering Reliable Pumping Solutions Across the UAE

At Khansaheb Sykes, we continue to support critical infrastructure projects across the UAE with dependable pump hire solutions, technical expertise, and dedicated on-site service. The successful hydrotesting at this major Dubai facility demonstrates our ability to adapt equipment and methodologies to meet demanding site conditions – ensuring projects stay on track, no matter the challenge.

Download Case Study

Download case study: Digester Tank Hydrotesting at Sewage Treatment Plant, Dubai

Do you have a complex pumping project involving difficult access or high-pressure requirements?

Get in touch with our outstanding team today for the successful management of your project’s toughest tasks.

Find out more about our pump hire services here.